Gate Valve Type, Advantage and Disadvantage, Applications

Gate Valve, Type, Advantage and Disadvantage, Applications

Gate valves are widely used for all types of applications and are suitable for both above-ground and underground installation. Not least for underground installations, it is paramount to choose the right type of valve to avoid high replacement costs.

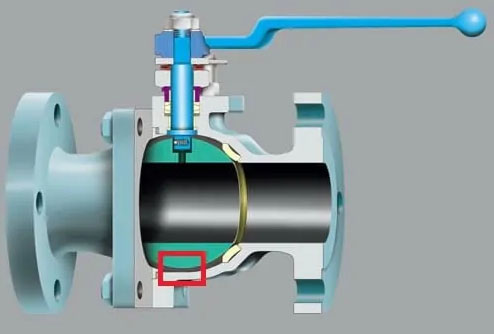

Gate valves are designed for fully open or fully closed service. They are installed in pipelines as isolating valves, and should not be used as a control or regulating valves.

Operation of a gate valve is performed doing an either clockwise to close (CTC) or clockwise to open (CTO) rotating motion of the stem. When operating the valve stem, the gate moves up- or downwards on the threaded part of the stem.

History of a gate valve

History of a gate valve

The term Gate Valve originated from the words gatan, gap, gasse and gat, and implies a passage with a barrier, which can be hinged on one side, allowing it to be OPENED and CLOSED.

Some of the first known gate valves were used by the Egyptians, Greeks, and Romans when irrigating fields with water. These were simple wooden barriers, but they were well-suited for the requirements of the task.

In the 19th century, intensive development of gate valves moved quickly forward due to their increasing use in industrial operations. Over time the materials involved in their manufacture were improved and modified to suit different applications.

In addition, there were significant improvements in the efficiency of both internal and external sealing methods.

Type of Gate Valve

There is a different type of gate valve, such as:

- Standard

- Wedge Types

- Solid Tapered Wedge

- Solid Pliable Wedge

- Double Disc type

- Bellow Design

- Cryogenic Design

- Knife Plate

- Hulk Plate

Advantages of Gate Valves

- The closing feature is very good.

- These valves can be used both ways in the circuit

- They provide laminar flow, the pressure loss is minimum

Disadvantages of Gate Valves

- They cannot be opened and closed quickly. To fully open or closed wheel or gearbox actuators, the shaft should be rotated as many as the full open revolution number. The full open revolution number is equal to the pitch

- Assembly, start-up, and maintenance require large space.

- In the fully closed position, the slow movement of the slide causes high flow speed. Due to vibration and collision, abrasion and deformation occur in the seating surfaces and the surface gets damaged from friction.

- In systems where high-temperature changes irregularly, due to the load in the pipe at the valve end, leakages in gate valves occur.

- At the place of operation, repair and maintenance of seating surfaces are difficult.

Application of Gate valve

- Socket or butt-welding end-gate valves in air, fuel gas, feedwater, steam, lube oil, and other systems are typical applications. Threaded-end gate valves may be used in air, gaseous, or liquid systems.

- Concern for leakage from threaded connection can be addressed by seal welding the threaded connection or by using thread sealants, as appropriate. In low-pressure and low-temperature systems such as fire protection systems’ water piping or water distribution pipelines, flanged gate valves are commonly used.

Refrences: