Pressure Gauge

Below you will see some of the best-selling types of manometers that you can choose based on the type of use.

Types of pressure gauges

manometers have analog and digital types, the analog gauge has a lower price than the digital one, and in some cases, the accuracy of the digital one is more than the analog one.

Bourdon tube pressure gauge

Bourdon tube manometer is suitable for liquid and gaseous processes or media. All steel manometers are very suitable in applications where the process is aggressive, high viscosity, and non-crystalline.

Diaphragm pressure gauge

If the process pressure is high, a diaphragm is used for greater safety and more accurate pressure measurement. These diaphragms are used in environments with high viscosity and aggressive for high vibrations. Glycerin or silicone is used as oil.

Capsule pressure gauge

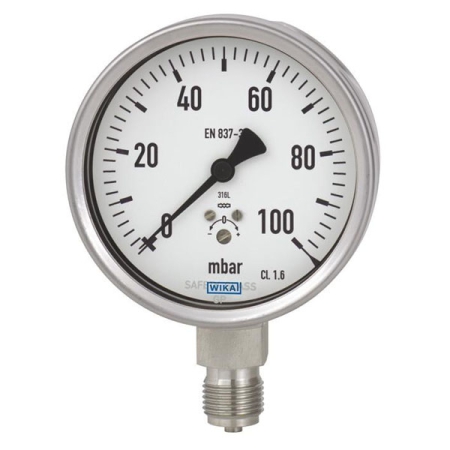

If the pressure is low in a process and the medium is gaseous, a capsule gauge with high accuracy is used. Two circular diaphragms are used to make these manometers, which are connected around the edge with a tight seal that protects against excessive pressure.

Absolute manometer

Absolute pressure measuring instrument is used when pressures are measured independently of natural atmospheric pressure fluctuations.

Differential pressure gauge

For example, these differential manometers control the flow of gaseous and liquid media and the amount of deposition in treatment plants.

In general, the price of the manometer with materials such as steel will be more expensive than brass models.

Fluid pressure measurement in various processes is always a very important issue that is done by pressure measuring instruments such as manometers these instruments have different types.

- Display 15 Products per page

Types of pressure gauges based on the function

In general, perhaps as the most important classification of pressure measurement instruments, based on the type of structure and their function, it has been classified into two main categories:

Analog pressure gauge and Digital pressure gauge.

Classification of pressure gauges based on application:

- Clean room manometer

- Oxygen manometer

- Thermomanometer

- differential pressure gauges

- Manostat

Types of pressure gauges based on the measuring mechanism:

- Bourdon

- Diaphragm

- Millibar or capsule gauge

- Absolute pressure gauge

Dry or oily category

In general, pressure gauges are divided into two general categories: oil or dry manometer.

- Dry manometer

- Oil manometer

Classification of pressure gauges based on material:

- Stainless steel

- Brass steel manometer

- Brass manometer

Stainless steel pressure gauge

The body and connection model of this manometer, in fact, is made of steel. It is one of the most widely used and of course popular models in various industries and is mostly used in special fluids such as acids that are corrosive.

They have different dimensions and types and are widely used in measuring and controlling pressure.

Pressure gauge Applications

- Chemical and petrochemical industries

- Machine building industry

- Oil and gas extraction

- Drilling Industry

- Rubber industry

- Manufacturing factories

- The medical and pharmaceutical industry

- Food and beverage factories

- air conditioning

- Refrigeration

- Level measurement

- Fluid flow measurement

- Leak detection

- Hydraulic and pneumatic equipment

- Electricity production and power plants

- laboratory equipment

Things to consider When purchasing a manometer are:

- Manufacturing Country

- brand

- Digital and analog

- material

- Connection type

- Pressure sensor type

- Page size

- precision

- Size and type of connection

- Explosion Proof

Parameters to consider when buying pressure gauge

The important points in buying a pressure gauge are to measure pressure in different industries and factories.

Before buying, it is better to pay attention to the determining factors of this pressure measuring equipment and make the right choice according to the needs and working conditions of industrial processes.

For example, if your work process is in high safety conditions, you should use explosion-proof gauges, or to measure the amount of millibar pressure, you should use millibar gauges, which are charged at a higher rate than usual gauges when buying. you turn