Bimetal thermometer with switch contacts

Bimetal thermometer with switch contacts

Wherever the process temperature has to be indicated locally and, at the same time, limit values must be monitored, thermometers with switch contacts find their application.

The switch contacts make or break the circuit dependent upon the pointer position of the indicating measuring instrument. If the reading is significantly above or below a set value, they trigger an alarm, hence also the term “alarm contact”. The instruments are also suitable for starting, stopping or switching processes

Wherever the process temperature has to be indicated locally, and, at the same time, circuits are to be made or broken, the bi-metal thermometer with switch contact can be used.

The switch contacts are adjustable over the full extent of the scale range. The instrument pointer (actual value pointer) moves freely across the entire scale range, independent of the setting.

The set pointer can be adjusted using a detachable adjustment key (mounted to the junction box) in the window.

Switch contacts consisting of several contacts can also be set to a single setpoint. Contact actuation is made when the actual value pointer travels beyond or below the desired set value.

As switch contacts sliding contacts, inductive contacts – for requirements to ATEX – or electronic contacts for triggering a PLC are available.

Application

- Control and regulation of industrial processes

- Monitoring of plant and switching of electric circuits

- The chemical industry, petrochemical industry, process technology, and food industry

- For aggressive medium

Technical Features

- High reliability and long service life

- Universal application

- Case and stem material stainless steel

- Gauges with inductive contacts for use in hazardous areas with ATEX approval

- Gauges with electronic contacts for PLC applications

Measuring element

- Bimetal coil

Nominal size in mm

- 100

Connection designs

- S Standard (threaded connection)

- 1 Plain stem (without thread)

- 2 Male nut

- 3 Union Nut

- 4 Compression fitting (sliding on the stem)

- 5 Union nut and loose threaded connection

Accuracy class

- DIN 16196

Working range

- Normal (1 year): Measuring range (DIN 16196)

- Short time (24 h max.): Scale range (DIN 16196)

Case and bayonet ring

- Stainless steel 1.4301

Stem and process connection

- Stainless steel 1.4571

Dial

- Aluminium white, black lettering

Window

- Instrument glass

Pointer

- Aluminum, black, adjustable pointer

Electrical connection

- Cable terminal box

Permissible operating pressure at the stem

- max. 25 bar, static

Permissible ambient temperature at case

- -20 … +60 °C (others on request)

Temperature limits for storage and transport

- -20 … +60 °C (EN 13190)

Ingress protection

- IP65 per IEC/EN 60529

Switch contacts

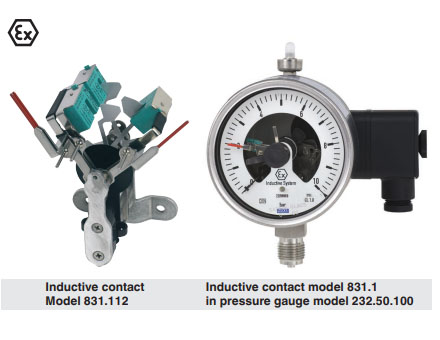

Inductive contact model 831

- Long service life due to non-contact sensor

- Additional control unit required

- With corresponding control unit suitable for use in zone 1 / 21 (2 GD) hazardous areas

- Low influence on the indication accuracy

- Fail-safe switching at the high switching frequency

- Insensitive to corrosion

- Up to 2 switch contacts per measuring instrument

Electronic contact model 830 E

- For direct triggering of a programmable logic controller (PLC)

- No additional control unit required

- Long service life due to non-contact sensor

- Low influence on the indication accuracy

- Fail-safe switching at the high switching frequency

- Insensitive to corrosion

- Up to 2 switch contacts per measuring instrument

Switching function

- The switching function of the switch is indicated by index 1 or 2.

- Model 8xx.1: Normally open (clockwise pointer motion)

- Model 8xx.2: Normally closed (clockwise pointer motion)