Types of Valves

Types of Valves

In the industry, we have different Types of Valves , each with a specific application. In this article, we introduce the most widely used valves.

BALL VALVES

A ball valve is a shut-off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. By rotating the ball a quarter turn (90 degrees) around its axis, the medium can flow through or is blocked.

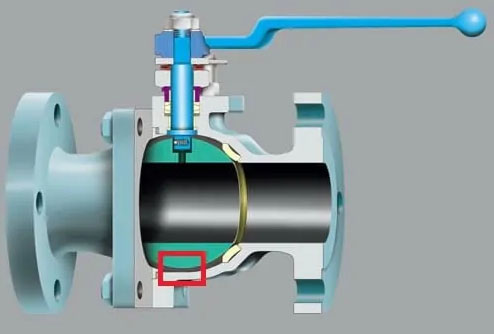

Floating Ball Valve

In floating ball valve, the ball is held in the position by the compression of the two elastomeric seats against the ball. The ball is free to float inside the valve body. See the highlighted portion in the image and remember as you will see the difference when I will explain you about trunnion mounted ball valve.

Trunnion Mounted Ball Valve

Trunnion mounted ball valve is a solution to the problem of excessive torque required by floating ball valve in high-pressure service. A short shaft like an extension that called trunnion set in the body. You can see this in the image. In this design steam and ball work as a single unit. The ball is supported by two floating or spring-loaded seats that remain in constant contact with the ball.

Gate Valve

Gate valves are widely used for all types of applications and are suitable for both above ground and underground installation. Not least for underground installations it is paramount to choose the right type of valve to avoid high replacement costs.

Gate valves are often used when minimum pressure loss and a free bore is needed. When fully open, a typical gate valve has no obstruction in the flow path resulting in a very low pressure loss, and this design makes it possible to use a pipe-cleaning pig. A gate valve is a multiturn valve meaning that the operation of the valve is done by means of a threaded stem. As the valve has to turn multiple times to go from open to closed position, the slow operation also prevents water hammer effects.

Globe Valve

A globe valve is a linear motion valve used to stop, start, and regulate the fluid flow. The globe valve disk can be removed entirely from the flow path, or it can completely close the flow path. During opening and closing of globe valve, disc moves perpendicularly to the seat.

This movement creates the annular space between the disk and seat ring that gradually close as the valve closed. This characteristic provides the globe valve good throttling ability required for regulating the flow.

Leakage from globe valve seat is less as compared to the gate valve, mainly due to right angle contact between the disk and seat ring, which allows tighter seal between seat the disk.

CHECK VALVES

Leak-free, tight sealing, protection against reverse flow and minimal flow direction changes are at the core of Flowserve check valve designs. A broad range of configurations that includes piston, tilting disc, spring-loaded disc and dual-plate models meets the critical, high-temperature/pressure demands of the world’s major industries. Customers can carefully match application requirements through myriad valve body, seat and disc options.

https://hardhatengineer.com/ball-valve-floating-trunnion-mounted-ball-valves/

https://hardhatengineer.com/globe-valve-types-angle-parts/

https://www.flowserve.com/en/products/valves/check-valves

Leave a Reply

Want to join the discussion?Feel free to contribute!