Adjustable Dial thermometer WIKA model S55

Adjustable Dial thermometer WIKA model S55

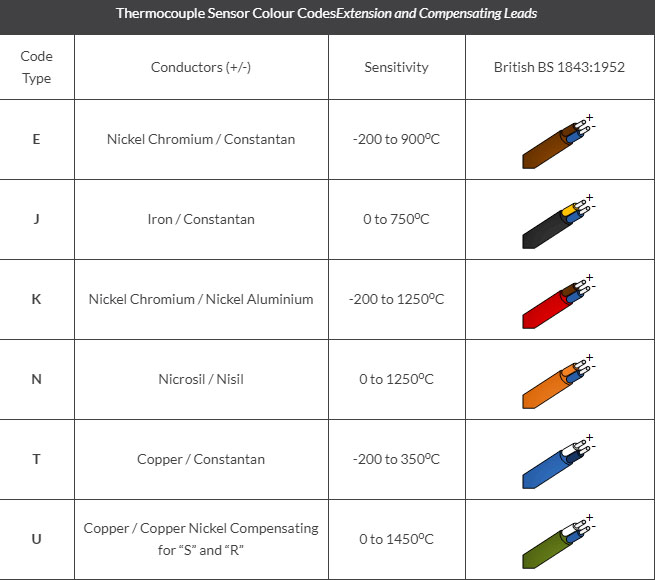

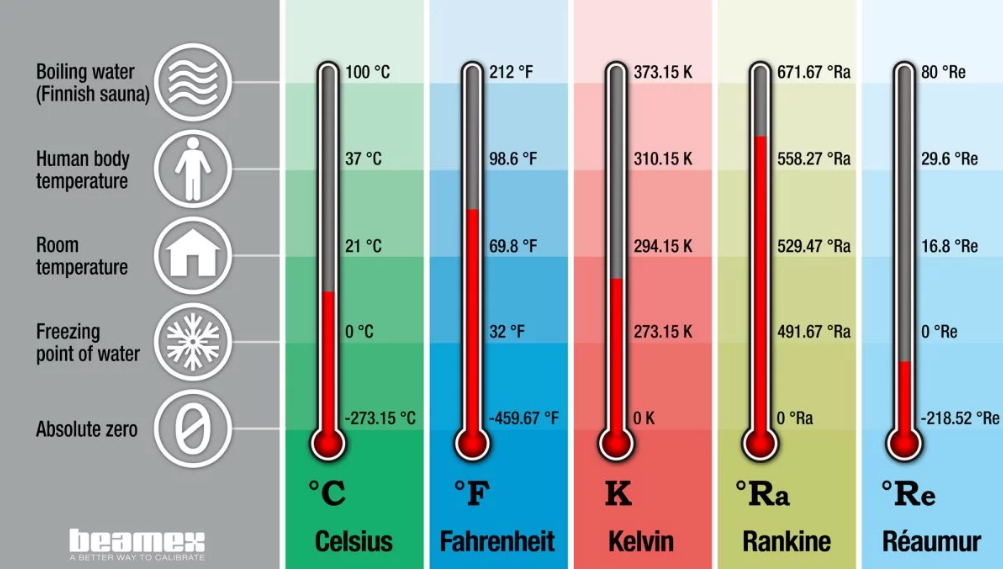

Adjustable Dial thermometer work on the bimetal, expansion or gas actuation principle. This enables scale ranges of -200 to +700 °C in different class accuracies, response times and resilience to environmental influences. Diverse connection designs, stem diameters, and individual stem lengths enable a flexible measuring point design. All thermometers are suited for operation in a thermowell if necessary.

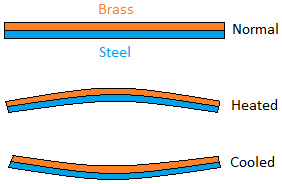

What is Bimetallic Thermometer

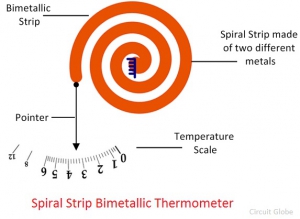

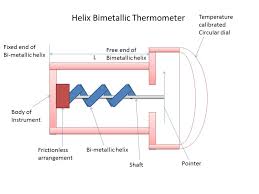

The bimetallic thermometer consists of a bimetallic strip. A bimetallic strip is made of two thin metals which have different coefficients of expansion. The two metal strips are joined together by brazing, welding or riveting so that the relative motion between them is arrested. The bimetallic strip is in the form of a cantilever beam. An increase in temperature will result in the deflection of the free end of the strip This deflection is linear and can be related to temperature changes. The radius of the curvature of the bimetallic strip which was initially flat is determined using the following relationship.

Model S50 WIKA thermometer

The model 55 bimetal thermometer has been developed and is manufactured in accordance with the EN 13190 standard. The high-quality thermometer has been designed especially for the requirements of the process industry. The temperature measuring instrument completely manufactured from stainless steel. The model 55 satisfies the high requirements for resistance against aggressive media. As an option, the case, the stem, and the process connection can be made from 316Ti (1.4571) to fulfil the highest requirements.

To allow optimum fitting to the process, individual insertion lengths and different process connections can be selected. When it comes to harsh climatic conditions at the place of use, model 55 is the right choice. It can be used at temperatures ranging from -40 °C to +70 °C (optional also up to -50 °C or -70 °C).

Applications

- General process instrumentation in the

- chemical and petrochemical industries

- oil and gas industries

- energy and water/wastewater industries

- Temperature measurement in harsh and aggressive environments

Technical Features

the scale ranges

- from -70 … +600 °C

Measuring element

- Bimetal coil

Nominal size in mm

- 100

- 160

Connection designs

- S: Standard (male threaded connection)

- 1: Plain stem (without thread)

- 2: Male nut

- 3: Union Nut

- 4: Compression fitting (sliding on the stem)

- 5: Union nut and loose threaded connection

Model

Model S5550

Back mount, adjustable stem, and dial

- Dial: 100mm

Model S5551

Back mount, adjustable stem, and dial

- Dial: 160mm

Material

The case, bayonet ring

- Stainless steel 1.4301 (304)

Stem, process connection

- Stainless steel 1.4571 (316Ti)

Dial

- Aluminium white, black lettering

Window

- Instrument glass

Zero adjustment

- on the case back side, external only for adjustable stem and dial (option)

Insertion length

- L1 63 … 1,000 mm

minimum/maximum length is dependent on the measuring range and diameter

Temperature limits for storage and transport

- -50 … +70 °C

Permissible ambient temperature

- -40 … +70 °C (with/without filling liquid)

Permissible operating pressure at the stem

- max. 25 bar, static

Ingress protection

- IP65 per IEC/EN 60529

Gas-actuated Thermometers

Gas-actuated Thermometers Bimetal Thermometer

Bimetal Thermometer