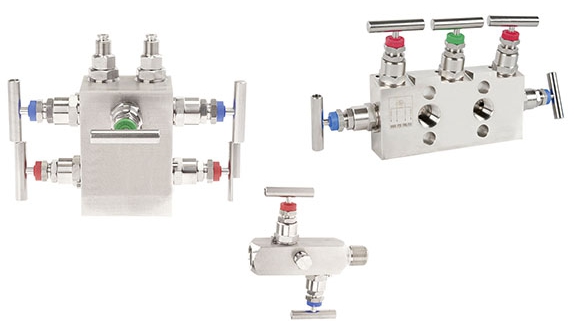

Valve Manifold

Valve Manifold

The Valve Manifold used to protect the DP transmitter and pressure gauge from a higher range. This device isolates the transmitter from fluid pressure for calibration and for maintenance purposes.

The manifold is a combination of valves in a single body. Each valve will have separate openings ad controls. The manifolds commonly use the ball, bleed, needle, and vent valves.

3-valve manifold

The 3-valve manifold consists of two shut-off valves and one pressure compensating valve. The shut-off valves separate the process from the differential pressure measuring instrument. The pressure compensating valve enables the compensation between ⊕ side and ⊖ side to avoid one-sided overpressure during commissioning and operation.

5-valve manifold

Compared to the 3-valve manifold, the 5-valve manifolds equipped with two additional vent valves. One vent valve per pressure side allows operators the targeted venting of one or both pressure sides of the measuring arrangement.

Through the non-rotating spindle tip, the wear of the sealing elements is reduced. This results, particularly with frequent opening and closing, in a noticeable increase in the service life of the valve manifold.

Advantages of a manifold valve

Manifold valves are used in a number of different applications, ranging from mobile machinery to heavy industrial equipment.

When included in fluid control and/or regulation system, valve manifolds have shown to improve efficiency as well as reduce energy costs. Other advantages include:

- Shorter path flows which reduces pressure drop and heat fluctuations, improving the overall energy efficiency of the system

- Reduction in installation costs as well as fluid connections because of a simpler, more compact design

- Minimum chances of oil leak due to less number of connections, further reducing the need for upkeep against fatigue, wear and lose joints

- Improved layout due to fewer hoses and connections

- Small, compact cartridge sizes which suits confined spaces

Applications

- Shut off and vent pressure measuring instruments

- For gaseous and liquid aggressive media that are not highly viscous or crystallizing, also in aggressive environments

- Process industry: Oil & gas, petrochemical, chemical industries, power generation, water, and wastewater

Leave a Reply

Want to join the discussion?Feel free to contribute!