Diaphragm Pressure Gauge

Diaphragm Pressure Gauge

Diaphragm Pressure Gauge are preferably used for low-pressure ranges. Through the large working surface of the circular, corrugated diaphragm element, small pressure ranges can be measured reliably.

Diaphragm pressure gauges are considered as specialists in the process industries. They come into play when Bourdon tube pressure gauges reach the limits of their performance. One of the advantages of diaphragm pressure gauges is the measurement of low pressures.

It is suitable for all gaseous and liquid media, as well as for viscous media and suspended solids. When a force acts against a thinly stretched diaphragm, it causes a deflection of the diaphragm with its center, deflecting the most.

Applications of the diaphragm pressure gauge

- For measuring points with increased overload

- With liquid-filled case suitability for high dynamic pressure loads and vibrations

- For gaseous, liquid and aggressive media, also in aggressive environments

- With the open connecting flange option also for contaminated and viscous media

Industries:

- Chemical

- petrochemical

- power plants

- mining

- on-/offshore

- environmental technology

- machine building

- and general plant construction

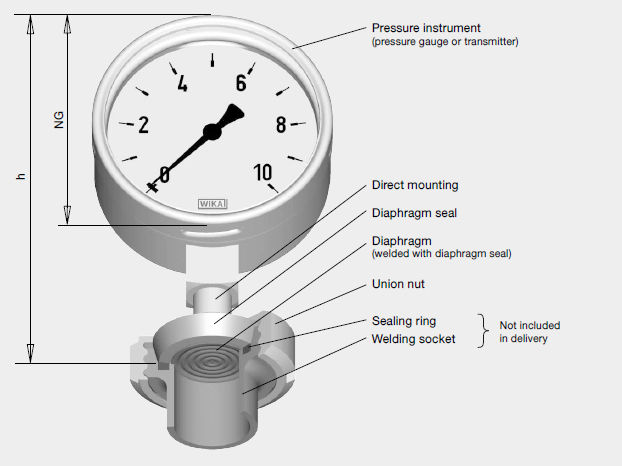

Diaphragm pressure gauges are suitable for gauge, absolute and differential pressure. Their core, the diaphragm element, is a circular, corrugated diaphragm which is clamped or welded between two flanges. This element is generally manufactured from resilient steels such as stainless steel or Inconel. On pressure loading, the deflection of the pressure element, proportional to the incident pressure, is transferred to a movement via a link. (see Figure 1)

The usable diaphragm travel is as short as approximately one millimeter, which offers high repeatability. However, this characteristic is related to corresponding standards for quality and tolerances of the diaphragm materials.

In addition to the material itself, the material strength, waveform, and diameter determine the metrological characteristics of the diaphragm, and with this, the quality of the measuring result for the appropriate measuring range. Diaphragm elements basically possess a corrugated profile. A smooth metal diaphragm would deform plastically under loading and would, therefore, make a precise pressure measurement impossible.

Diaphragm pressure gauges Advantages:

- Excellent load performance

- Linearity

- Suitable for measuring absolute pressure, differential pressure

- Small size, affordable

- Can be used for viscous, slurry measurement.

Diaphragm pressure gauge Disadvantages:

- Seismic, impact resistance is not good

- Difficulty in maintenance

- Lower measurement pressure

Leave a Reply

Want to join the discussion?Feel free to contribute!