Valve Symbol

Valve Symbol

A valve regulates, directs, or controls the flow of a fluid by opening, closing, or partially obstructing passageways in a piping system. This category includes rotameters, orifices, and other types of valves.

Piping and instrumentation diagrams, or P&IDs, are used to create important documentation for process industry facilities. The shapes in this legend are representative of the functional relationship between piping, instrumentation, and system equipment units.

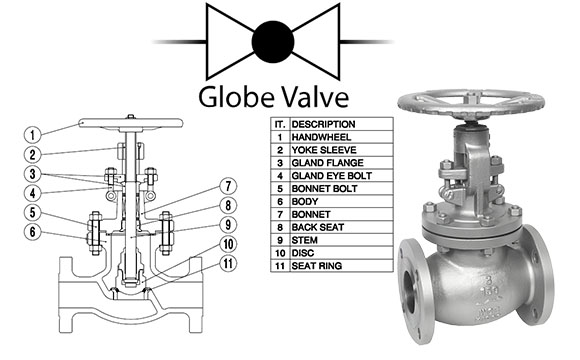

Globe Valve

A globe valve is a linear motion valve used to stop, start, and regulate the fluid flow. The globe valve disk can be removed entirely from the flow path, or it can completely close the flow path. During opening and closing of globe valve, disc moves perpendicularly to the seat.

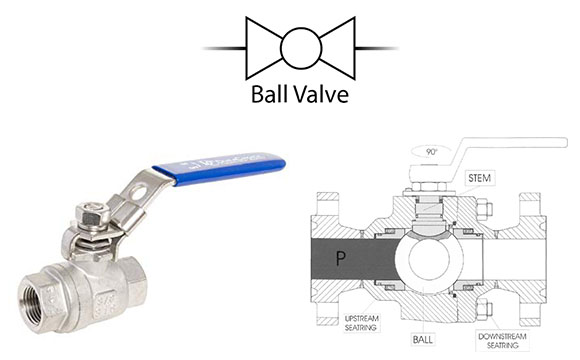

Ball Valve

Ball valves are quarter-turn, straight-through valves that have around closure element with matching rounded seats that permit uniform sealing stress. The valve gets its name from the ball that rotates to open and close the valve. Ball valves are used in situations where tight shut-off is required. They are wide duty valves, able to transfer gases, liquids, and liquids with suspended solids (slurries).

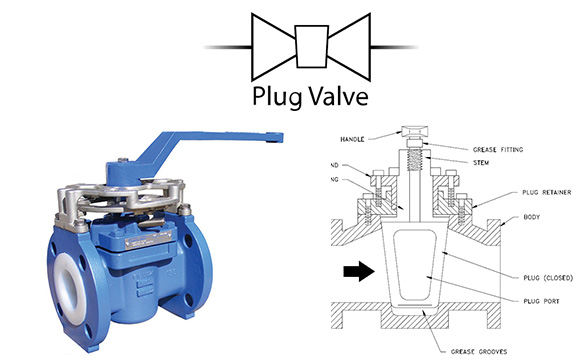

Plug Valve

A plug valve is shaped like a cylinder or cone and can be rotated inside the valve body to control flow of fluids. Plug valves have one or more hollow passageways often placed horizontally to allow ease of flow through the valve when open. The most common type of plug valve is the 2 port model with an open and closed position. The two ports are usually located on opposite sides of the valve with one passageway leading from inbound to outbound and the stem and handle located on the top. A plug valve also uses a quarter turn valve, which is useful where the quick and frequent operation is essential. The valve ends can be flanged, hub type, or butt weld.

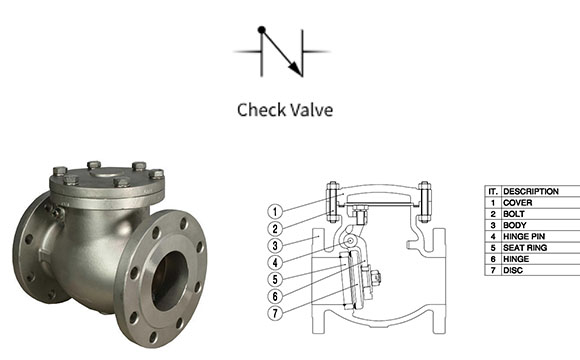

Check Valve

The valve that used to prevent backflow in a piping system is known as a check valve. It is also known as a non-return valve or NRV. The pressure of the fluid passing through a pipeline opens the valve, while any reversal of flow will close the valve. It allows full unobstructed flow and automatically shuts as pressure decreases. The exact operation will vary depending on the mechanism of the valve.

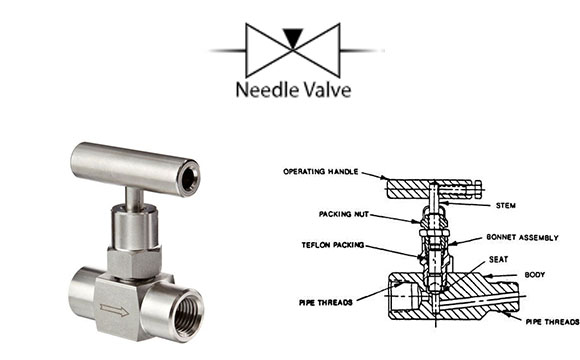

Needle Valve

A needle valve is a manual valve that used where continuous throttling of flow is required for regulation. Needle valves are similar to the globe valve in design with the biggest difference is the sharp needle like a disk.

Needle valves are designed to give very accurate control of flow in small diameter piping systems. They get their name from their sharp-pointed conical disc and matching seat.

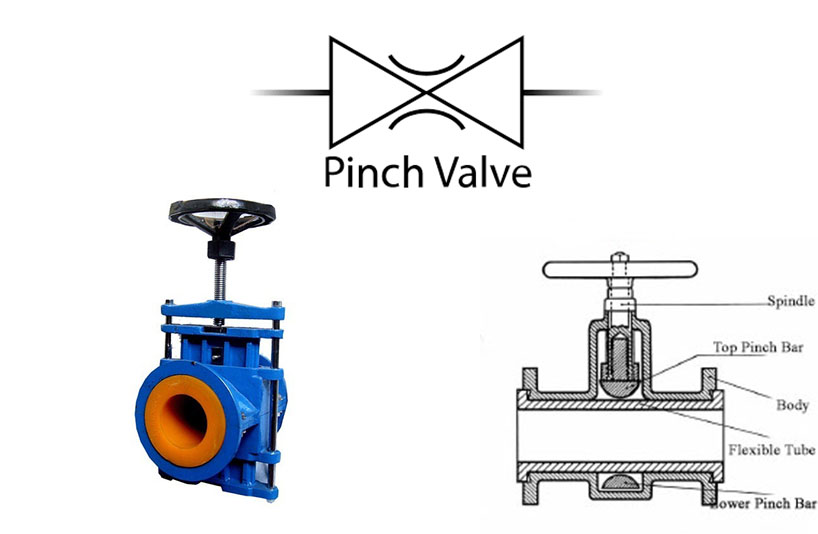

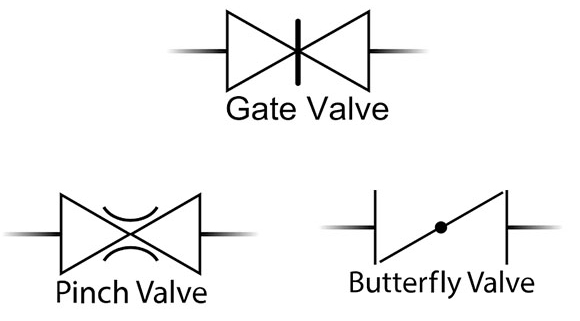

Pinch Valve

A Pinch Valve is an economical piece of equipment that works like a tap. It has an on/off function, to shut off, allow or control the flow of any media passing through it. The Pinch Valve is made up of three parts: Body / Housing, Internal rubber sleeve, End connections.

The rubber sleeve inside the body of the valve is the part that closes it. When in the open position, the Pinch Valve has a full and true bore. To close the valve, air pressure is supplied into an air nipple on the outer body, which then travels through into the internal part of the valve, pushing down onto the rubber sleeve which fully collapses and closes tightly.

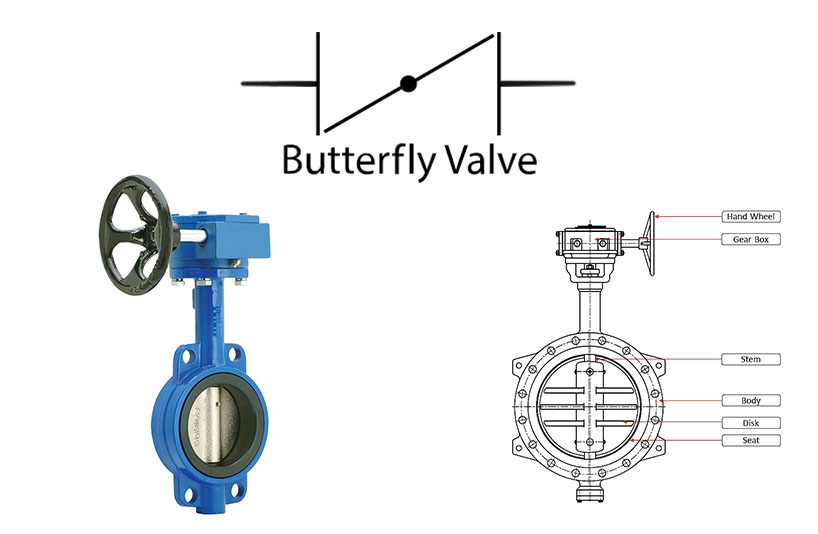

Butterfly Valve

A butterfly valve is a flow regulating disc valve. A butterfly valve consists of a circular disc or plate built with a stem through the middle or attached offset. When opened, the disc pivots 90 degrees in the valve bore, aligning with the flow, creating a nearly unrestricted flow path. Butterfly valves operate similarly to ball valves in their 90-degree rotation and allow for quick shutoff.

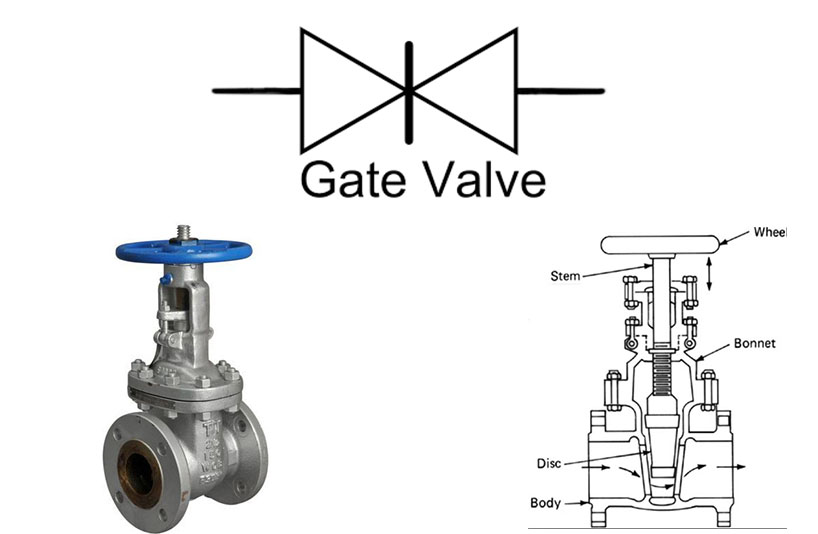

Gate Valve

Gate valves are designed for fully open or fully closed service. They are installed in pipelines as isolating valves, and should not be used as a control or regulating valves. Operation of a gate valve is performed doing an either clockwise to close (CTC) or clockwise to open (CTO) rotating motion of the stem. When operating the valve stem, the gate moves up- or downwards on the threaded part of the stem.

Gate valves are often used when minimum pressure loss and a free bore is needed. When fully open, a typical gate valve has no obstruction in the flow path resulting in a very low-pressure loss, and this design makes it possible to use a pipe-cleaning pig. A gate valve is a multiturn valve meaning that the operation of the valve is done by means of a threaded stem. As the valve has to turn multiple times to go from open to closed position, the slow operation also prevents water hammer effects.

Leave a Reply

Want to join the discussion?Feel free to contribute!