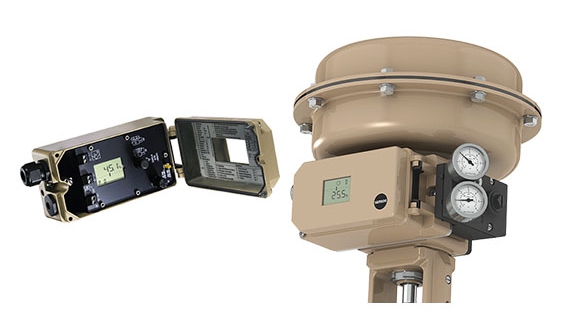

Valve Positioner Samson

Valve Positioner Samson Type 3730

A valve Positioner is a device used to increase or decrease the air load pressure driving the actuator until the valve’s stem reaches a “POSITION” balanced to the output SIGNAL from the process variable instrument controller.

Valve positioners are used on controlling valves where accurate and rapid control is required without error or hysteresis.

Positioners are generally mounted on the side-yoke or top casing of the pneumatic actuator for linear sliding stem control valves, and at/near the end-of-shaft for rotary control vales. For either basic design type, “mechanical feedback linkage” connected directly to the valve’s stem provides feedback to the controller. The process controller tells the positioner to “change” position; the feedback linkage reports back to the positioner confirming that a change has occurred and gives a “sense” of the magnitude of the change in position.

Type 3730-0 Electropneumatic Positioner

Application

- Single-acting or double-acting positioner for attachment to pneumatic control valves

Setpoint

- 4 to 20 mA

Travel

- 5.3 to 200 mm

Special features

- Simple attachment to common linear actuators with an interface for SAMSON direct attachment, NAMUR rib, valves with rod-type yokes according to IEC 60534-6 and attachment according to VDI/VDE 3847

- Any desired mounting position of the positioner

- Calibrated travel sensor without gears susceptible to wear

- Analog pneumatic output prevents pulsing in case of leaking actuator

- The fast-reacting analog control loop

- High control accuracy (fine tuning) without the dead band and continuous pneumatic output

- The two-wire system with a small electrical load below 300 Ω for explosion-protected version and version without explosion protection

- Output pressure limitation enabled by DIP switch

- Selectable tight-closing function with fixed switching point

- Low air consumption of approx. 110 ln/h independent of supply and output pressure

- Aluminum housing with IP 66 degree of protection

- Check valve in the exhaust airport

- Resistant to shock and vibrations

- Extended temperature range also for intrinsically safe operation

- Travel range selectable within the rated travel range by

setting DIP switch - Zero and span adjusted by potentiometers

- Setpoint range and direction of action adjustable

Type 3730-1 Electropneumatic Positioner

Application

- Single-acting or double-acting positioner for attachment to pneumatic control valves. Self-calibrating, automatic adaptation to valve and actuator.

Setpoint

- 4 to 20 mA

Travels

- 3.75 to 200 mm

Opening angle

- 24 to 100°

Special features

- Simple attachment to all common linear and rotary actuators with an interface for SAMSON direct attachment, NAMUR rib or valves with rod-type yokes according to IEC 60534-6-1, or to rotary actuators according to VDI/ VDE 3845

- Any desired mounting position of the positioner

- Simple single-knob, menu-driven operation

- LCD easy to read in any mounted position due to the selectable reading direction

- Variable, automatic start-up

- Preset parameters – only values deviating from the standard need to be adjusted

- Calibrated travel sensor without gears susceptible to wear

- Permanent storage of all parameters in EEPROM (protected against power failure)

- A two-wire system with a small electrical load of 300 Ω

- The tight-closing function can be activated

- Continuous monitoring of zero point

- Two standard programmable position alarms

Type 3730-2 Electropneumatic Positioner

Type 3730-2 Electropneumatic Positioner

Application

- Single-acting or double-acting positioner for attachment to pneumatic control valves. Self-calibrating, automatic adaptation to valve and actuator.

Setpoint

- 4 to 20 mA

Valve travel

- 3.6 to 300 mm

Opening angle

- 24 to 100°

Special features

- Simple attachment to all common linear and rotary actuators

- Any desired mounting position of the positioner (but not suspended)

- Simple single-knob, menu-driven operation

- LCD easy to read in any mounted position due to the selectable reading direction

- Configurable with a PC over the SSP interface using the TROVIS-VIEW software

- Variable, automatic start-up with four different initialization modes

- Preset parameters – only values deviating from the standard need to be adjusted

- Calibrated travel sensor without gears susceptible to wear

- Sub initialization mode (substitution) allows the positioner to be started up in case of emergency whilst the plant is running without the valve moving through the whole travel range.

- Permanent storage of all parameters in EEPROM (protected against power failure)

- A two-wire system with a small electrical load between 300 and 350 Ω depending on version Adjustable output pressure limitation

- Activatable tight-closing function

- Continuous monitoring of zero point

- Integrated temperature sensor and operating hours counter

- Two standard programmable position alarms

- Self-diagnostics; alarms as condensed state conforming to NAMUR Recommendation NE 107, issued over a fault alarm contact or optional analog position transmitter

- Integrated EXPERTplus diagnostics for control valves

Type 3730-3 Electropneumatic Positioner with HART communication

Application

- Single-acting or double-acting positioner for attachment to pneumatic control valves. Self-calibrating, automatic adaptation to valve and actuator.

Setpoint

- 4 to 20 mA

Valve travel

- 3.6 to 300 mm

Opening angle

- 24 to 100°

Special features

- Simple attachment to all common linear and rotary actuators

- Any desired mounting position of the positioner (but not suspended)

- Simple single-knob, menu-driven operation

- LCD easy to read in any mounted position due to the selectable reading direction

- Configurable with a PC over the SSP interface using the TROVIS-VIEW software

- Variable, automatic start-up with four different initialization modes

- Preset parameters – only values deviating from the standard need to be adjusted

- Calibrated travel sensor without gears susceptible to wear

- Sub initialization mode (substitution) allows the positioner to be started up in case of emergency whilst the plant is running without the valve moving through the whole travel range.

- Permanent storage of all parameters in EEPROM (protected against power failure)

- A two-wire system with a small electrical load of 410 Ω

- Adjustable output pressure limitation

- Activatable tight-closing function

- Continuous monitoring of zero point

- Integrated temperature sensor and operating hours counter

- Two standard programmable position alarms

- Self-diagnostics; alarms as condensed state conforming to NAMUR Recommendation NE 107, issued over a fault alarm contact or optional analog position transmitter

- Integrated EXPERTplus diagnostics for control valves

Type 3730-4 Electropneumatic Positioner with PROFIBUS-PA communication

Application

- Positioners for attachment to pneumatic control valves

Valve travel

- from 3.6 to 300 mm ·

Opening angle

- 24 to 100°

Special features

- PROFIBUS-PA Profile 3.01 certified positioner fulfilling all compulsory requirements of PROFIBUS-PA Profile 3.02

- Automatic ID adaptation according to PROFIBUS-PA Profile 3.02 to facilitate the replacement of positioners with Profile 2.0 or 3.0 (e.g. Type 3785)

- Classified status alarms acc. to NAMUR Recommendation NE 107

- DTM file available to integrate the positioner into FDT/ DTM in compliance with specification 1.2

- Simple attachment to all common linear and rotary actuators

- Any desired mounting position of the positioner (but not suspended)

- Single-knob, menu-driven operation

- Automatic start-up

- LCD easy to read in any mounted position due to the selectable reading direction

- Integrated EXPERTplus diagnostics for control valves

- Online changing of control parameters

- Automatic zero monitoring

- Calibrated travel sensor without gears susceptible to wear

- Permanent storage of all parameters (protected against power failure)

- Negligible influence of temperature and supply air

- Adjustable output pressure limitation

- Activatable tight-closing function

- Binary input for DC voltage signals

Leave a Reply

Want to join the discussion?Feel free to contribute!