HIGH PERFORMANCE WAFER STYLE BUTTERFLY VALVE SAMSON

HIGH-PERFORMANCE WAFER STYLE BUTTERFLY VALVE

A butterfly valve is a shut-off valve with a relatively simple construction. In the closed position, the disc blocks the valve bore while in open position, the disc is turned to allow flow. A quarter turn takes the valve from fully open to the fully closed position or the opposite, and thus the butterfly valve allows for quick opening and closure.

Butterfly valves can be used for a broad range of applications within water supply, wastewater treatment, fire protection, and gas supply, in the chemical and oil industries, in fuel handling systems, power generation, etc. Some of the advantages of this type of valve are the simple construction not taking up too much space, and the lightweight and lower cost compared to other valve designs.

The valves can be operated by handles, gears or actuators according to any specific need.

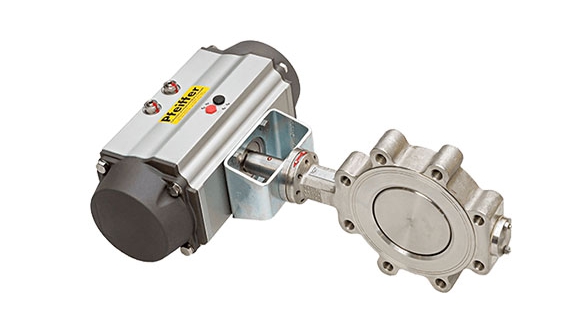

The Pfeiffer BR14a double eccentric control butterfly valve is designed for general service applications up to the limits of the ANSI 150 pressure class rating. These general service applications include process events such as erosion, abrasion, and corrosion.

The Pfeiffer BR14a design increases flow capacities but also reduces the pressure recovery factor making the design more susceptible to cavitation, flashing, and flow noise generation. The double eccentric design of this butterfly valve will reduce the breakaway torques required from the actuator.

The Pfeiffer BR14a control butterfly valve has standard options such as low and high-temperature version. The Pfeiffer BR14a and BR14b can be assembled with a pneumatic, electric, hydraulic, or electro-hydraulic actuator. These control valves are designed according to the modular assembly principle, can be equipped with SAMSON GROUP actuators and valve accessories such as positioners, limit switches, and solenoid valves.

Technical Specification

Size

- 3″ to 20″

ANSI Class

- 150

Std. Materials

- Carbon Steel, Stainless Steel

Temperature Range

- 14 to 392oF (-10 to 200oC)

FEATURES & BENEFITS

- Minimum material required compared to similar sized control valves of different types

- The pneumatically actuated valve can be stroked extremely quickly

- Double Eccentric disk design provides a tight seal, reduced breakaway torque and wear

- Anti-blowout valve shaft design to increase reliability

- Extended valve neck to allow easy installation in insulated pipelines

- Soft seat rings can be replaced with metal seat rings on site

- Throttling service rangeability is 50:1

Applications

- Food & Beverage

- Water & Wastewater

- Iron & Steel

- Chemical & Petrochemical

Leave a Reply

Want to join the discussion?Feel free to contribute!